Rare earth samarium cobalt magnets, shorted as SmCo magnets, are a type of powerful permanent magnet made from the basic elements samarium and cobalt and other metal rare earth materials by mixing, melting, grinding, pressing and sintering. They come in various sizes and shapes, like disc,bar, ring, arc,block, etc.,. Similar to neodymium strong magnets, they belong to the rare earth magnet category, and tcan be classified as SmCo5 and Sm2Co17 according the composition ratios of samarium and cobalt.

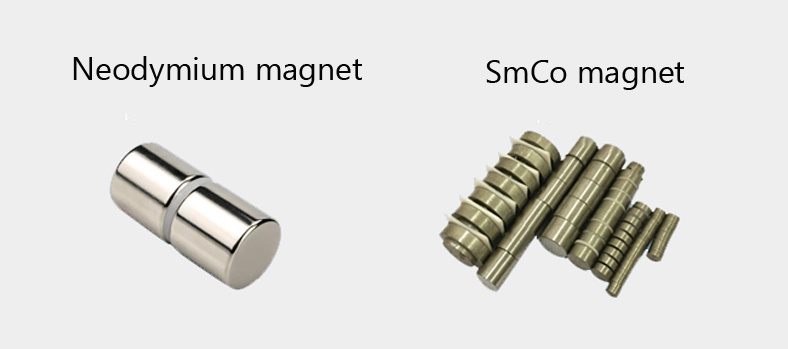

In comparison to neodymium rare earth magnets, although samarium cobalt magnets may not have as strong magnetic force, they possess two distinct advantages. Firstly, they operate effectively within a higher temperature range, and secondly, they exhibit greater resistance to corrosion.

Due to these characteristics, rare earth SmCo magnets are commonly employed in applications that demand high operating temperatures, such as generators, pump couplings, sensors, electric motors, marine applications, as well as in the automotive, racing, aerospace, military, and food and manufacturing industries. SmCo rare earth magnets not only perform well at high temperatures but also maintain their magnetic properties even in temperatures below absolute zero (-273 degrees Celsius), making them popular for use in low-temperature applications.

SmCo Disc Magnets

Unleash magnetic prowess with Samarium Cobalt (SmCo) disc magnets. Offering intense strength, these rare earth discs excel in high-temperature applications.

SmCo Block Magnets

Explore the strength of Samarium Cobalt (SmCo) block magnets – ideal for high temperatures. Choose resilience and magnetic power for your applications!

SmCo Bar Magnets

Unlock the potential of Rare Earth Samarium Cobalt (SmCo) bar magnets. Ideal for high temperatures and custom applications, we offer varied grades for optimized performance.

SmCo Cylinder(rod) Magnets

Experience unmatched magnetic power with our Samarium Cobalt Cylinder Magnets – renowned for exceptional strength and corrosion resistance. Ideal for challenging environments and high-temperature applications.

SmCo Ring Magnets

Discover the strength of Samarium Cobalt ring magnets – optimal performance, high coercivity, and corrosion resistance. Explore Sm1Co5 and Sm2Co17 varieties for superior applications.

SmCo Rectangular Magnets

Unleash the strength of samarium cobalt rectangular magnets – handle with care for optimal performance in diverse industrial applications.

SmCo Arc Magnets

Elevate your applications with Samarium Cobalt Arc Magnets, known for robust performance and excellent heat resistance. Ideal for motors, sensors, and aerospace.

SmCo(Samarium Cobalt) Countersunk Ring Magnet

Rare earth SmCo countersunk ring magnets have very high coercivity, which means they are not easy to demagnetize. SmCo countersunk ring magnets are known by their ability to work at temperatures up to...

Square SmCo Magnets

Square samarium cobalt magnets, a type of rare earth permanent magnet, boast high magnetic energy and an extremely low temperature coefficient.

Samarium cobalt magnets (SmCo magnets) are a crucial type of permanent magnet known for their high magnetic energy product and excellent magnetic stability. Their versatile applications contribute to various industries:

1. Electric Motors: The exceptional magnetic properties of samarium cobalt make it an ideal material for crafting efficient electric motors. These rust proof magnets of SmCo not only enhance the power density of motors but also reduce their size and weight, thereby improving overall motor efficiency.

2. Sensors: Samarium cobalt magnets find utility in creating magnetic sensors. They enhance a sensor's sensitivity to external magnetic fields, thereby improving the sensor's responsiveness and accuracy.

3. Instruments and Gauges: Due to its high magnetic energy product and stable magnetization, samarium cobalt magnets are employed in the manufacturing of precision instruments and gauges.

4. Medical Devices: The heightened magnetic performance of samarium cobalt magnets is utilized in the fabrication of MRI (Magnetic Resonance Imaging) devices. These magnets contribute to creating a stronger and more stable magnetic field in MRI equipment, thereby enhancing imaging accuracy.

As technology advances and samarium cobalt magnet materials continue to improve, we anticipate their applications to expand further across diverse industries.

Samarium cobalt magnets offer numerous advantages, making them an ideal choice for industrial applications and contributing to their increasing popularity. In fact, in certain situations, rare earth SmCo magnets may be more suitable than neodymium magnets.

Benefits of Samarium Cobalt Magnets:

1. High Magnetization Field Strength: Samarium cobalt magnets have a higher maximum energy product than ferrite magnets, enabling them to generate a stronger magnetic field for high torque applications.

1. High Magnetization Field Strength: Samarium cobalt magnets have a higher maximum energy product than ferrite magnets, enabling them to generate a stronger magnetic field for high torque applications.

2. High Corrosion Resistance: These magnets exhibit excellent rust resistance and chemical stability, allowing them to function normally in harsh environments such as water, acids, and salt.

3. High Temperature Resistance: SmCo rare earth magnets have a broader temperature stability range compared to other permanent magnet materials, maintaining long-term stability even in high-temperature environments.

4. Ease of Processing: Samarium cobalt magnets are easily processed using methods such as drilling, milling, and grinding, owing to their good machinability.

Despite the various advantages of SmCo magnets, it's important to consider some factors when contemplating their use for your business applications. SmCo rare earth magnets can be brittle and perform best in applications where direct impact is not required. Additionally, these magnets are sensitive to market prices and are generally more expensive than neodymium magnets.

When comparing 2:17 type samarium cobalt permanent magnets to 1:5 type samarium cobalt magnets, the following advantages stand out:

Lower Cost Composition:

The formula of Sm2Co17 permanent magnets contains lower levels of cobalt and samarium compared to SmCo5 magnets. This significant reduction in raw material content results in cost savings, as both samarium and cobalt are relatively expensive rare metals. Consequently, Sm2Co17 magnets are priced lower than SmCo5 magnets.

Lower Magnetic Sensitivity to Temperature:

Sm2Co17 magnets have a lower magnetic sensitivity temperature coefficient of about -0.02%/℃, allowing them to operate in a range of -60 to 350℃. This is a distinct advantage over SmCo5 magnets, which cannot match this temperature versatility.

Higher Curie Temperature:

The Curie temperature of 2:17 type samarium cobalt materials is approximately 840-870℃, while the Curie temperature of 1:5 type samarium cobalt materials is 750℃. This indicates that 2:17 type samarium cobalt is more resistant to high temperatures than 1:5 type samarium cobalt. However, it's important to note that the manufacturing process for 2:17 type samarium cobalt is more complex compared to 1:5 type samarium cobalt. Achieving higher coercivity requires a longer aging process, resulting in higher production costs compared to SmCo5.

In the realm of permanent magnets, Sm2Co17 magnetic materials show promise as high-temperature magnets.

Material | Grade | Energy Product BH(max) | Residual Induction | Coercive Force Hcb(min-max) | Intrinsic Coercive Force Hcj(min-max) | Density | Max work Temp. | ||||

KJ/m3 | MGoe | T | KGs | KA/m | KOe | KA/m | KOe | g/cm3 | ℃ | ||

SmCo5 | XG16 | 120-143 | 15-18 | 0.77-0.86 | 7.7-8.6 | 613-716 | 7.7-9.0 | ≧1194 | ≧15 | 8.3 | 250 |

XG16H | 120-143 | 15-18 | 0.77-0.86 | 7.7-8.6 | 613-716 | 7.7-9.0 | ≧1592 | ≧20 | |||

XG18 | 135-159 | 17-20 | 0.81-0.92 | 8.1-9.2 | 637-756 | 8.0-9.5 | ≧1194 | ≧15 | |||

XG18H | 135-159 | 17-20 | 0.81-0.92 | 8.1-9.2 | 637-756 | 8.0-9.5 | ≧1592 | ≧20 | |||

XG20 | 151-175 | 19-22 | 0.85-0.95 | 8.5-9.5 | 637-756 | 8.0-9.5 | ≧1194 | ≧15 | |||

XG20H | 151-175 | 19-22 | 0.85-0.95 | 8.5-9.5 | 637-756 | 8.0-9.5 | ≧1592 | ≧20 | |||

XG22 | 167-191 | 21-24 | 0.89-1.00 | 8.9-10 | 661-772 | 8.3-9.7 | ≧1194 | ≧15 | |||

XG22H | 167-191 | 21-24 | 0.89-1.00 | 8.9-10 | 661-772 | 8.3-9.7 | ≧1592 | ≧20 | |||

Sm2Co17 | XGS24M | 175-199 | 22-25 | 0.92-1.04 | 9.2-10.4 | 318-788 | 4.0-9.9 | 398-1194 | 5.0-15.0 | 8.4 | 350 |

XGS24 | 175-199 | 22-25 | 0.92-1.04 | 9.2-10.4 | 661-796 | 8.3-10.0 | 1194-1990 | 15.0-25.0 | |||

XGS24H | 175-199 | 22-25 | 0.92-1.04 | 9.2-10.4 | 661-804 | 8.3-10.1 | ﹥1990 | ﹥25.0 | |||

XGS26M | 191-215 | 24-27 | 1.00-1.06 | 10.0-10.6 | 318-796 | 4.0-10.0 | 398-1194 | 5.0-15.0 | |||

XGS26 | 191-215 | 24-27 | 1.00-1.06 | 10.0-10.6 | 677-820 | 8.5-10.3 | 1194-1990 | 15.0-25.0 | |||

XGS26H | 191-215 | 24-27 | 1.00-1.06 | 10.0-10.6 | 677-820 | 8.5-10.3 | ﹥1990 | ﹥25.0 | |||

XGS28M | 207-231 | 26-29 | 10.4-11.0 | 10.4-11.0 | 318-804 | 4.0-10.1 | 398-1194 | 5.0-15.0 | |||

XGS28 | 207-231 | 26-29 | 10.4-11.0 | 10.4-11.0 | 677-820 | 8.5-10.3 | 1194-1990 | 15.0-25.0 | |||

XGS28H | 207-231 | 26-29 | 10.4-11.0 | 10.4-11.0 | 677-820 | 8.5-10.3 | ﹥1990 | ﹥25.0 | |||

XGS30M | 223-247 | 28-31 | 10.7-11.2 | 10.7-11.2 | 318-804 | 4.0-10.1 | 398-1194 | 5.0-15.0 | |||

XGS30 | 223-247 | 28-31 | 10.7-11.2 | 10.7-11.2 | 700-828 | 8.8-10.4 | 1194-1990 | 15.0-25.0 | |||

XGS30H | 223-247 | 28-31 | 10.7-11.2 | 10.7-11.2 | 700-828 | 8.8-10.4 | ﹥1990 | ﹥25.0 | |||

XGS32M | 231-255 | 29-32 | 10.9-11.5 | 10.9-11.5 | 318-804 | 4.0-10.1 | 398-955 | 5.0-12.0 | |||

XGS32 | 231-255 | 29-32 | 10.9-11.5 | 10.9-11.5 | 716-836 | 9.0-10.5 | ﹥955 | ﹥12.0 | |||

XGS22LT | 159-183 | 20-23 | 9.0-9.9 | 9.0-9.9 | 677-756 | 8.5-9.5 | ≧1194 | ≧15.0 | |||

XGS24LT | 159-183 | 20-23 | 9.2-10.2 | 9.2-10.2 | 677-756 | 8.5-9.5 | ≧1194 | ≧15.0 | |||

SmCo(1:5) magnets have better mechanical and physical properties than SmCo(2:17) magnets, which is slightly easier to process

If SmCo magnets are used in acid-base environment and another bad environment, electroplating treatment can be adopted on the them, Nickel-coated SmCo magnets, Zinc-coated SmCo magnets, Epoxy-coated SmCo magnets etc can be supplied

If you need un-magnetized SmCo magnets,you should be familiar with the magnetizing energy of your magnetizing equipment, so as to choose the correct grades of SmCo magnets which can be completely full magnetized.

Differences Between Samarium Cobalt and Rare Earth Neodymium Magnets:

1. Magnetic Strength: Rare earth NdFeB magnets are renowned as the "king of magnetism" for their formidable strength, surpassing samarium cobalt magnets, which rank just below neodymium iron boron in magnetic performance.

2. Temperature Resistance: Rare earth neodymium magnets reaches a maximum temperature of 220 degrees only with materials of 28AH and above, while Sm2Co17 can withstand temperatures up to 350 degrees. Around 300 degrees, neodymium iron boron loses magnetic force, while samarium cobalt can operate normally without requiring demagnetization.

3. Stability: Rare earth neodymium magnets exhibits a large residual magnetism temperature coefficient, decreasing residual magnetism with rising temperatures. In contrast, samarium cobalt magnets have a smaller residual magnetism temperature coefficient, with minimal demagnetization and higher stability. Neodymium requires plating to prevent oxidation, corrosion, and weathering, while samarium cobalt with cobalt coating often doesn't require plating, ensuring a longer lifespan and appealing aesthetics.

4. Price: Neodymium rare earth magnets contain small amounts of rare earth elements neodymium and boron, making it relatively more affordable. On the other hand, samarium cobalt magnets contain a higher proportion of rare earth elements samarium and cobalt, resulting in a higher price.

Conclusion: Compared to rare earth NdFeB magnets, samarium cobalt magnets excel in higher temperatures and more corrosive environments. While neodymium magnets boast stronger magnetic fields and the highest BHMax in today's permanent magnets, samarium cobalt provides superior performance in specific conditions and is priced higher due to its composition of rare earth elements samarium and cobalt.

For retail, we have high quality standard magnets assemblies with wide selection range for sale at cheap price(include mounting pot magnets, magnetic hooks, fishing magnets, magnetic bases and office magnets); For special applications, we can quickly provide the best magnetic application solutions.