NdFeB magnets are also known as industrialized "monosodium glutamate". As an excellent permanent magnet material in contemporary industry, they promote the development of today's processing technology industry and the times, and are widely used in all walks of life.

(1) NdFeB magnets - magnetic properties.

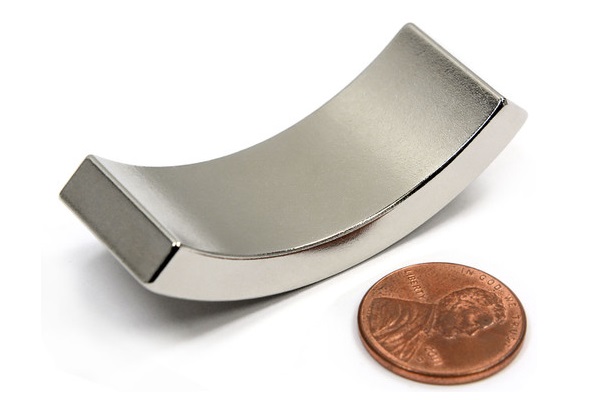

(2) NdFeB magnets - the size of the magnets.

(3) Surface ndfeb magnets coating of NdFeB magnets.

(1) The raw material manufacturer needs to calcine NdFeB in mid-range or low-grade according to the business process. According to the industry standard of raw materials, the company's market sales of NdFeB should be qualified.

(2) The innovation of the production process also determines the functional quality of the magnet.

(3) Quality supervision in the production process is crucial.

For raw materials of different specifications, different CNC lathes are used to cut rough raw materials, and production processing and equipment operation are done well. Excellent production technology determines the precision of enterprise products.

The surface coating solves the quality of the coating, and the ndfeb strong magnet is galvanized, nickel, copper, electroplated copper alloys, etc., and the electroplating process options can be carried out for the equipment according to user needs.

Master the standard tolerance of magnet characteristics, and distinguish the appearance inspection and evaluation of the coating. To test the standard tolerance of gauss of magnetic flux of magnets, the color and chromaticity of precision coatings and the adhesion of coatings can be accurately measured with a vernier scale. According to the appearance, observe whether the surface of the magnet is smooth and has no color spots, as well as falling edges and corners to analyze the quality.

(1) Try not to get close to the electronic equipment with the super strong magnet, as it will harm the electronic product and control circuit and directly affect the application.

(2) Magnets should not be stored in wet and cold conditions to prevent changes in appearance, physical properties and magnetic energy caused by air oxidation.

(3) People who are sensitive to metal objects will cause rough skin and redness if they approach the rubber coated mounting magnets. If you will have the above reaction, please try not to touch the super strong magnet.

(4) Do not place NdFeB magnets close to hard disks, disk drives, overdraft cards, tapes, savings cards, TV picture tubes, etc. If the magnet is close to the magnetic monitoring software and other components, it will harm or even destroy the recorded data information.

Related Article

Please fill the form to let us know your need. Our sales will get in touch with you ASAP.